Home / Our Stories /

West Gate Tunnel completes launch site with 4500 tonnes of reinforcing steel

10 September 2019

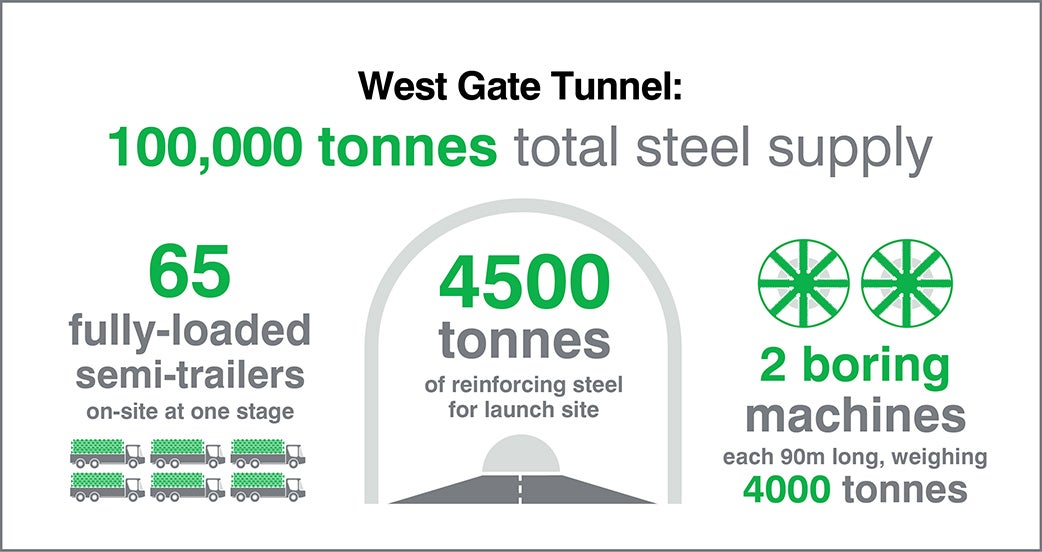

With the installation of 4500 tonnes of reinforcing steel, part of a total of 100,000 tonnes to be supplied by InfraBuild, the West Gate Tunnel Project’s Footscray launch site is now complete. Watch the project timelapse.

InfraBuild Construction Solutions (formerly LIBERTY OneSteel Reinforcing) has enabled the completion of a critical milestone in the early stages of the West Gate Tunnel Project, with the delivery of 4500 tonnes of reinforcing steel for the first stage of the project’s Tunnel Zone.

Dhjango Henry, CPBJH Joint Venture’s Project Manager – Northern Portal for the West Gate Tunnel Project, praised the contribution made by the InfraBuild Construction Solutions team.

“This is an iconic project that will help reshape Melbourne’s future, with reinforcing steel playing an essential role,” he said.

“Included in the contracts with InfraBuild is an order for approximately 100,000 tonne of reinforcing steel, which is one of the largest single orders for Australian reinforcing steel in the country.”

The West Gate Tunnel Project is just one of a number of major transport infrastructure projects currently underway that is sourcing materials from local manufacturers and creating local jobs now and into the future.

The standard of steel fabrication in Victoria is world class and demand for high-quality locally milled steel for projects like the West Gate Tunnel will ensure Victorian steel manufacturers thrive for years to come.

Victoria’s infrastructure boom is creating hundreds of new steel manufacturing jobs in Victoria – and InfraBuild Construction Solutions has benefitted, with more than 150 additional jobs created across the business.

Tunnel launch site complete

The steel supplied by InfraBuild Construction Solutions for the project’s Northern Portal was used to construct a base slab with approximately 20,000 cubic metres of reinforced concrete to provide a stable site at the project’s Footscray worksite. The site is where the project’s two tunnel boring machines (TBMs), Bella and Vida, are being assembled to begin excavating the project’s twin tunnels.

Although completion of the base slab represents a significant milestone in the project, the 4500 tonnes of reinforcing steel delivered thusfar is a small fraction of the overall amount intended for the project. InfraBuild Construction Solutions has been contracted to deliver approximately 100,000 tonnes of reinforcing steel in total across all project zones, including the precast facility at Benalla in Victoria’s north.

Such is the overall scale of the West Gate Tunnel, it represents the biggest project ever undertaken by Infrabuild Construction Solutions in Victoria, stimulating a major investment in manufacturing facilities, manufacturing equipment and highly skilled people within InfraBuild Construction Solutions.

Complex challenges overcome

InfraBuild Construction Solutions’ Christian Pyndiah explained that the first stage of the project required a complex logistical solution with as many as 65 fully loaded semi-trailers on site at one point.

“That’s not a scene you’ll see on any major project across the country,” he said. “The decision was made to pre-manufacture steel and keep it in storage to make sure the steel fixers would not run out of work and to keep construction flowing.

“Early engagement with the project team was a key initiative,” Christian added, “with both teams needing to understand the challenges associated with manufacturing, logistics and on-site activities.

“Considering the complexity, size and challenges within the design and delivery of the project, to be involved in such an iconic and mega project has been an inspiring experience,” he said.

Getting Melbourne moving

The West Gate Tunnel launch site has taken a year and a half to build and is about twice the length of an AFL oval. Since its completion, crews have undertaken the process of lowering Bella and Vida into the ground in pieces for assembly underground using a gantry crane capable of lifting up to 500 tonnes. Once the underground assembly of Bella and Vida has been completed, commissioning will take place and tunnelling will commence soon after.

The TBMs, which weigh approximately 4000 tonnes and are 90m long, will travel in a south-westerly direction to connect the West Gate Freeway to Melbourne’s CBD, port and CityLink. Once the project is complete, the launch site will then become the future north entry and exit to the West Gate Tunnel.

The new tunnel will provide an alternative to the West Gate Bridge, with estimates that it will cut travel times from the west to Melbourne’s CBD by up to 20 mins. Over 9000 trucks are also expected to be taken off residential streets as a result of the new infrastructure.

Please contact us for any feedback or media enquiries about this content.

Subscribe to the

InfraBuild newsletter

Receive regular updates on news, case studies as well as the latest products and services.