Home / Our Stories /

Continuous Improvement: Contistretch automated tangle detection

13 December 2021

A new high-tech solution is detangling an old problem at InfraBuild’s Newcastle Rod Mill.

The Contistretch plant improves Dbar from rod mill coils into compact spools used by our customers. However, tangles can occur during this process which usually requires an operator to watch the high-speed lines and manually stop them to remove the tangles.

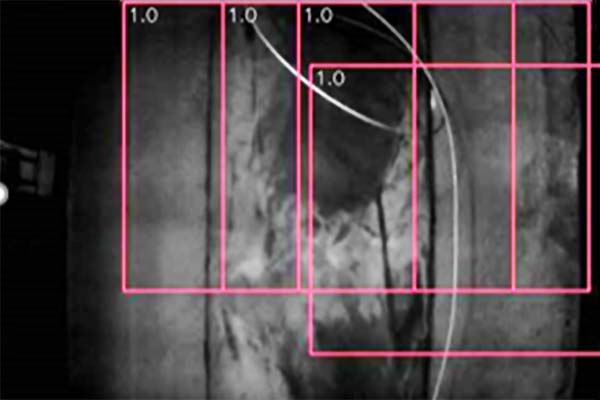

To address this difficult and labour-intensive task, the Contistretch team worked closely with automation company GEVA on an innovative project to develop a vision system to detect tangles and stop the lines automatically.

In what could be a world first, the vision system involves a camera monitoring bars passing through the payoff then uses image analysis with complex mathematical algorithms to identify a variance in pattern when a tangle is present.

During trials at the plant, our operators and technicians used their experience and know-how to give feedback which not only resulted in a new system being developed, but also improved lighting in the area and helped refine the complex algorithms used to identify tangles.

The system now works faster and more consistently than the manual process – reducing delays and improving safety. The automation has reduced the need for complex tangle removal and enable the operator to be re-assigned to other areas in the process thereby increasing overall throughput rates.

Due to its success, the vision system has been expanded to the new Line 3 – improving safety by reducing complex manual handling when removing tangles on the heavier 20mm bar.

Please contact us for any feedback or media enquiries about this content.

Subscribe to the

InfraBuild newsletter

Receive regular updates on news, case studies as well as the latest products and services.