Home / Our Stories /

‘Be prepared to adapt’ Hayden Dagg on starting your career in the steel industry

11 January 2024

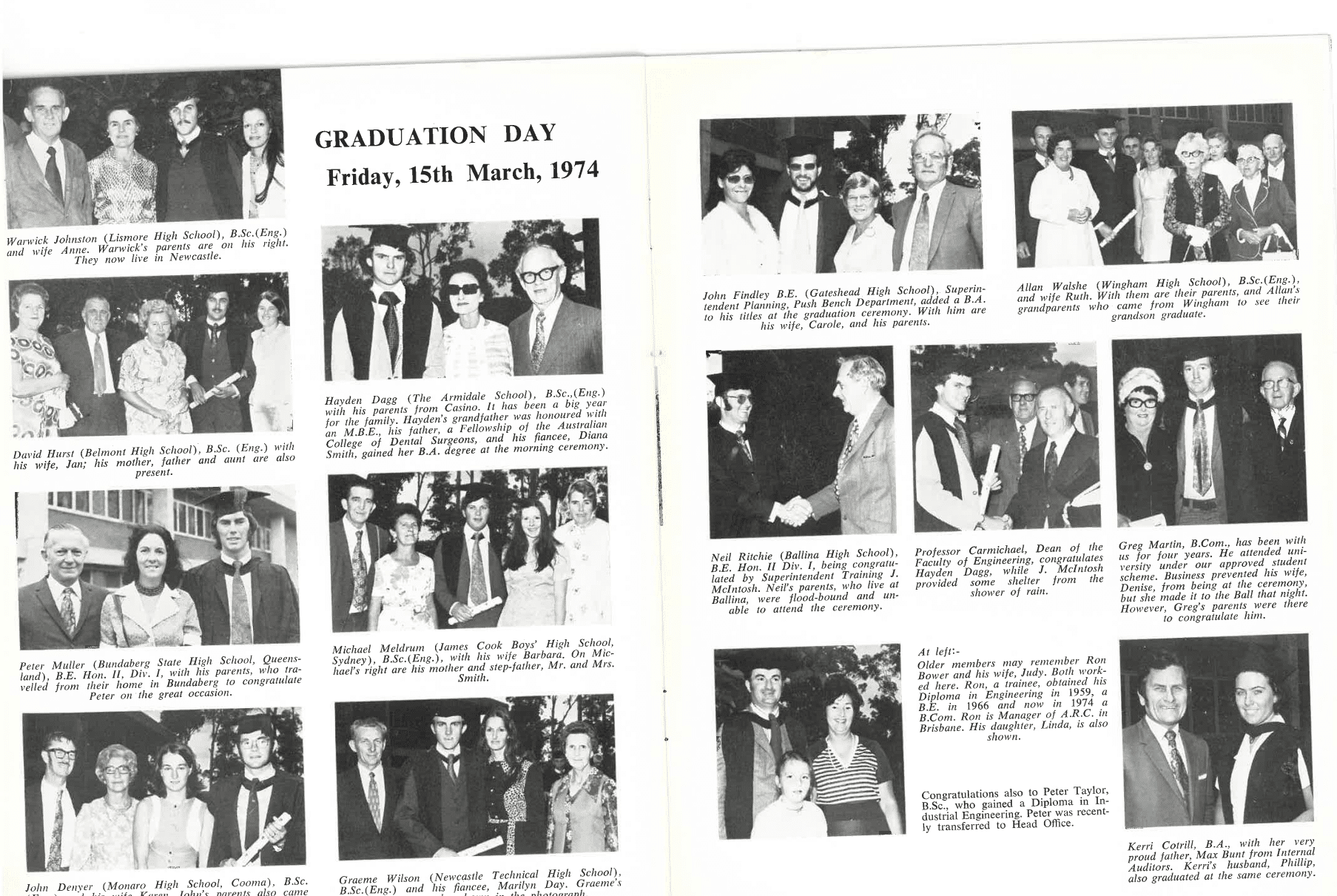

Hayden Dagg pictured with fellow Uni trainees, 1968

Hayden Dagg’s parents envisaged a career of equestrian/rural glory for their son, unfortunately, a horse-riding accident when he was 14 resulted in an 11 week stay in Grafton Hospital recovering. His injuries meant a rethink of career, which led to Hayden’s move from Casino to Newcastle. He was 18 looking for independence and a job. He found both at Stewart and Lloyd’s as an on-the-job trainee, he combined his practical experience with a science degree in engineering then became a welder.

Back in the early 1970’s, Stewart and Lloyd’s profiled their staff to help match them to job positions. Hayden didn’t match any specific role but Gilbert Christie, Industrial Psychologist, Personnel Department could see the potential in Hayden with his ‘can do’ attitude and natural curiosity and told him there would always be a job for him.

Hayden has made it his career mission to contribute to the development of niche products to meet market needs. The company Hayden joined – BHP Newcastle Steelworks and Stewarts, and Lloyds UK produced hot-formed welded water reticulation pipe for houses as well hot- formed seamless tube for pressure piping and rifle barrels. In the 1960’s Copper replaced the steel pipes due to its superior corrosion resistance and ease of joining. In the 70’s a move to manufacturing sections of cold-formed electric resistance welded square, rectangle and circular structural steel tubing ensured the longevity of the business.

In 2024, Hayden finds himself back in familiar territory, looking for opportunities to manufacture structural steel tube for power generation to support the emerging solar farm market.

Hayden more curious than most, has always been a forward thinker, he challenged the status quo not just at work but at home too. He built his first home for two reasons; to test commercial building principles for residential property to get an understanding of where hollow steel sections could be used and to save money. He now spends much of his free time doing maintenance on properties built before he was born.

When asked what drives Hayden to the office each day, he said the opportunity to transfer knowledge to others and the ability to tackle often challenging technical enquiries from customers.

Brett Willcox, Hayden’s Manager said: “Hayden has been a long-standing asset, he was instrumental to the evolution of tubular products and the continuation of tube manufacturing in Australia. His contribution to product development and innovation has helped to ensure tubular products are used in many applications”.

Hayden recalls personal career highlights that were instrumental to new product innovation; visiting high rise buildings under construction to understand floor vibration and participating in grape harvesting in the Clare and Barossa Valleys to understand trellis post performance.

From 55 years of experience, Hayden offers sage advice to those embarking on a steel career – be prepared to adapt to change in a creative, resourceful, and innovative way and search for the reason why, solve the problem!

Please contact us for any feedback or media enquiries about this content.

Subscribe to the

InfraBuild newsletter

Receive regular updates on news, case studies as well as the latest products and services.