The circularity of steel is well known and understood, its ability to be recycled over and over again, without loss of quality is part of the reason that it is globally the most recycled material by weight.

In Australia, according to the 2018 National Waste Report, around 90 per cent of all steel is captured at its “end of use” phase and re-enters the recycling supply chain as a valuable input to the EAF manufacturing process, destined to be turned back into new steel.

While steel can and is made using up to 100% scrap steel as the ferrous feedstock, and the recycled content of the new steel can be measured, recycled content only tells part of the circularity story, being as an input.

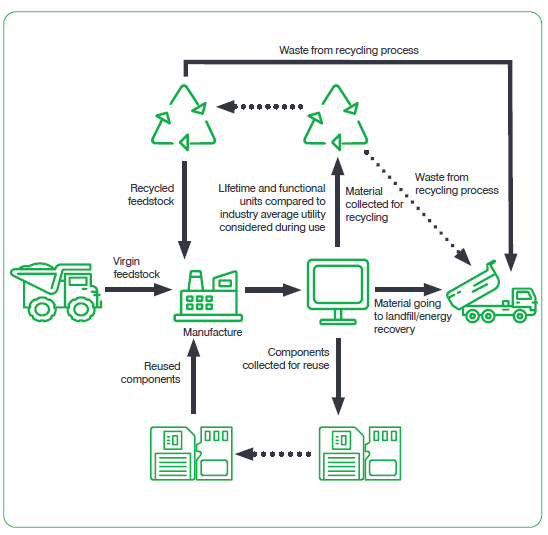

A more holistic approach is to measure and quantify the circularity of the steel product throughout its entire life cycle. This takes account of not just the recycled steel used to make the new steel product, but indeed all the inputs, including materials (both recycled and virgin) and energy (both fossil-fuel and renewables) used to make the new steel product. It also accounts for the waste outputs throughout the product’s life cycle that cannot be viably reused (including during the manufacturing, use and endof-use phases) and finally the recyclability of the steel at its end-of-life phase.

Quantification of this process is becoming increasingly important, as manufacturers, designers and end users look to understand the circularity of materials and products, and how this circularity can be improved.

The Ellen McArthur Foundation developed the Material Circularity Indicators (MCI) approach to be able to understand and measure the circularity of products. The MCI is particularly relevant to the building, construction, and infrastructure industries. It encourages more circular design principles, from the extraction of raw resources to construction, use, and eventual demolition and reuse or recycling. This process is demonstrated with the MCI tracking material flows from virgin stock, to use and eventual reuse. It focuses on the materials going in and the waste coming out at each step of a product’s lifecycle. It also considers a product’s utility when making the calculation, which includes the intensity of use and intended lifespan.

Sustainability specialist thinkstep-anz worked with InfraBuild to measure the circularity of all the steel products covered by InfraBuild’s EPDs. All five EPDs that were recently updated in 2022 include MCI results for the products in these EPDs. InfraBuild was the first business in Australia to include MCI metrics into their EPDs.

MCI metrics provide a number between 0 and 1 that can be used to benchmark and understand the circularity of a product, as well as a methodology for improving that circularity over time. MCIs also deliver additional value to an EPD, by providing a more complete picture of the overall sustainability credentials of that product.

As circular economy policies and sustainability rating schemes such as the GBCA Green Star and ISC IS tools develop and promote circular outcomes, InfraBuild through the provision of MCI metrics makes it easier to measure progress , performance and the ability to quantify the circularity of the products used in a project.

The results of InfraBuild’s work with thinkstep-anz delivers a benchmark to quantify each product’s circularity.

It also identifies key drivers that affect the MCI result and as such, further opportunities for InfraBuild to improve the MCI metrics into the future.

Increased use of the MCI approach and metrics for steel in projects will help the market to improve resource efficiency across the whole life of a project. InfraBuild is playing its part by transparently providing MCI results through its EPDs. This provides project teams with the ability to explore ‘circularity at scale’ for an entire building or infrastructure project and deliver more sustainable outcomes.

Please contact us for any feedback or media enquiries about this content.

Subscribe to the

InfraBuild newsletter

Receive regular updates on news, case studies as well as the latest products and services.