Companies are increasingly being held accountable for choices made across their supply chains, which means trust, transparency and traceability are more important than ever.

Never before have businesses had to apply rigour to their supply chains as they do now. Competitive pressures and the introduction of regulations across multiple levels of industry mean they must scrutinise their logistics networks to ensure sustainable practices are in place.

It isn’t just environmental requirements that businesses need to be concerned about, either – they must also safeguard that their supply chains are socially responsible and demonstrate that their materials comply with relevant Standards. The introduction of Australia’s Modern Slavery Act in January 2019 means that businesses must be vigilant about risks such as human trafficking in their supply chains.

InfraBuild (formerly LIBERTY OneSteel) occupies a leadership position in the Australian market in that it can offer its construction, manufacturing, mining and rural customers assurance and visibility at every point in the steel supply chain.

Under its new brand, InfraBuild has undergone a transformation process that makes it ideally placed to harness integrated solutions to ensure traceability in the product supply chain, stimulate new technologies and pursue strategies that minimise waste and help reduce, reuse or recycle products in the steel supply chain. Prioritising sustainability strategies will ensure InfraBuild reaches its target to be carbon neutral by 2030.

At the same time, InfraBuild is committed to pursuing socially responsible policies that support fair labour practices, encourage and embed diversity and inclusion in the workplace, and ensure slavery and human trafficking are eliminated from the supply chain.

“Customers are demanding increased transparency and traceability through their supply chains to ensure compliance to Standards and sustainability criteria,” explains InfraBuild Customer and Market Relationship Manager Rob Johnson.

“InfraBuild is focused on providing customers confidence in our supply chain – that the product they receive is the product they have specified and, ultimately, that it meets their requirements.

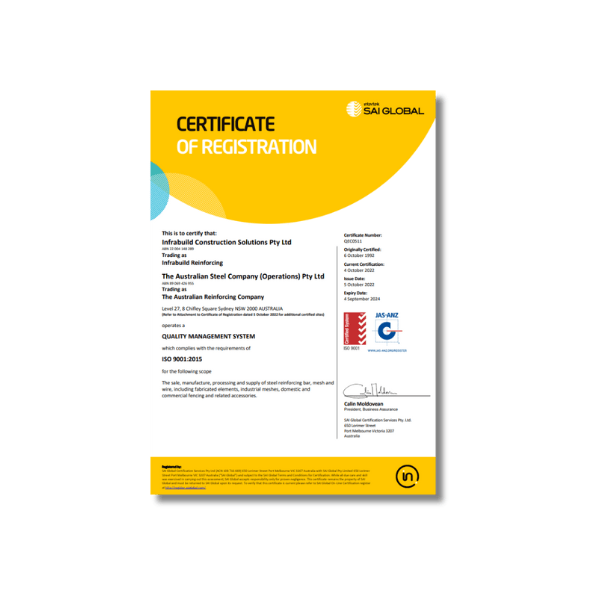

“We have transparency and traceability over each aspect of our fully integrated supply chain model, giving customers confidence that the material they procure meets their requirements. Our supply chain model is supported by rigorous third-party testing regimes to ensure that the product delivered meets project specifications and design intent,” Rob says.

Driving supply chain transformation

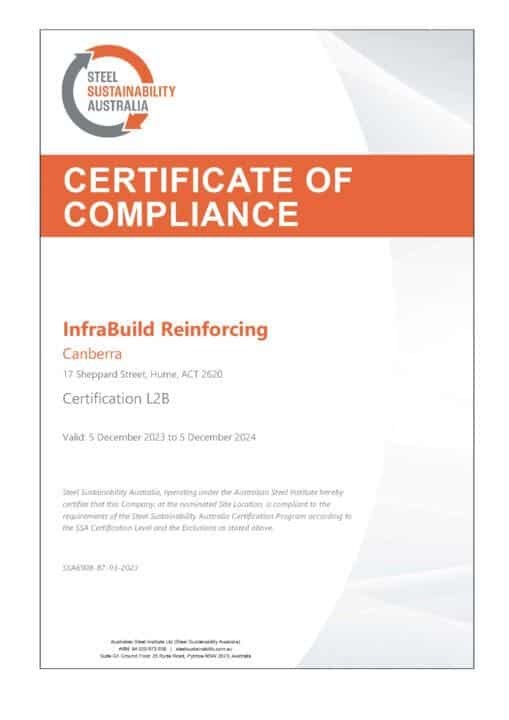

InfraBuild’s approach to ensuring the steel it supplies abides by sustainability standards is two-fold: it maintains a big-picture view of its supply network, while also furthering research into product tracking at a granular level.

Rob explains that InfraBuild is able to provide value to its customers by considering a broad range of factors and compliance requirements. “It’s really important to have a holistic, sustainable view of supply chains and not to focus on one particular aspect to the detriment of others,” he says.

“We are very aware of different issues at play, including making sure we know where all of our material is sourced from, which is key to maintaining a robust supply chain.”

InfraBuild also leads the way in applying global standards and technology to drive change in how products are tracked from manufacture through to delivery, as InfraBuild Customer Experience Manager David McNeil attests.

“For over 15 years, global data standards, especially the use of GS1 barcoding standards in the form of the global trade item number (GTIN), have been critical in InfraBuild’s efforts to facilitate electronic trading and product traceability,” David says.

“As the construction market increasingly demands full traceability of products throughout the supply chain for both compliance and sustainability, the serialised GTIN and its integration into building information modelling (BIM) is a logical and essential part of that journey,” David says.

Building on this foundation and utilising existing barcode technology along with GPS freight tracking, products can potentially be tracked at every stage in the supply chain. The valuable data acquired en route can then be used to increase traceability and contribute to improved efficiency in the planning and development of construction projects.

By investing in product traceability initiatives and by championing a range of integrated sustainability solutions, InfraBuild helps its customers apply the rigorous sustainability and compliance standards they need to complete their projects.

Please contact us for any feedback or media enquiries about this content.

Related Resources

Latest Resources

Subscribe to the

InfraBuild newsletter

Receive regular updates on news, case studies as well as the latest products and services.