Regulators, specifiers and builders have taken important steps to counter the use of non-compliant building products, including improving the Australian Standards covering the manufacture of structural steel and strengthening compliance measures. We spoke to David Bell, InfraBuild Business Development Manager, to find out what can be done to ensure steel compliance.

To view the webinar, click on the below:

Q: Issues relating to compliance have increasingly dominated discussion in recent years. Why is it important that the construction industry understands the need to use compliant building products?

A: Building and construction industry practitioners now firmly understand that a strong focus on compliance is not only in the public interest in terms of health and safety, but can deliver better environmental, social and economic outcomes.

The challenge presented by non-conforming products (NCPs) is that they can be found in almost every part of the construction market. Issues relating to glass, formwork, steel, windows, concrete and asbestos in building materials have been widely reported. There have also been instances of falsification of documentation and fraudulent labelling of building products.

The issue is an important one in Australia, which remains an attractive market for imported steel products of all kinds. During the height of the mining boom in 2013, approximately 600,000 tonnes of fabricated structural steel was imported into the country to be used in projects big and small. This amount was up from approximately 80,000 tonnes only a decade earlier.

Australia is not the only sophisticated construction market to feel the effects of an increasingly global procurement regime. A 2010 article in the highly regarded US engineering publication Engineering News Record showed that steel was the top counterfeit construction product imported into the US, with fasteners (i.e. bolts) in second place.

Q: What procedures have been put in place to ensure that the building products specified are those that are used? What work is ongoing?

A: The positive news is that the industry is becoming increasingly vigilant. Designers are aware that what they specify in their drawings is what should be used in the project, asset owners are seeking to protect their projects by eliminating NCPs from their supply chains, and governments understand that setting up and maintaining a regulatory regime is important to both industry and the community.

In 2013, the AiGroup released its report A Quest for a Level Playing Field in which it found that NCPs can have an impact not just on safety and business sustainability, but can increase maintenance costs and reduce asset value.

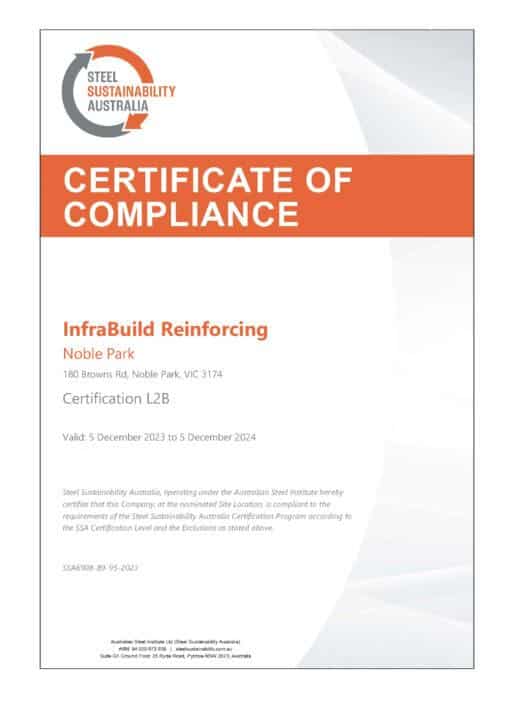

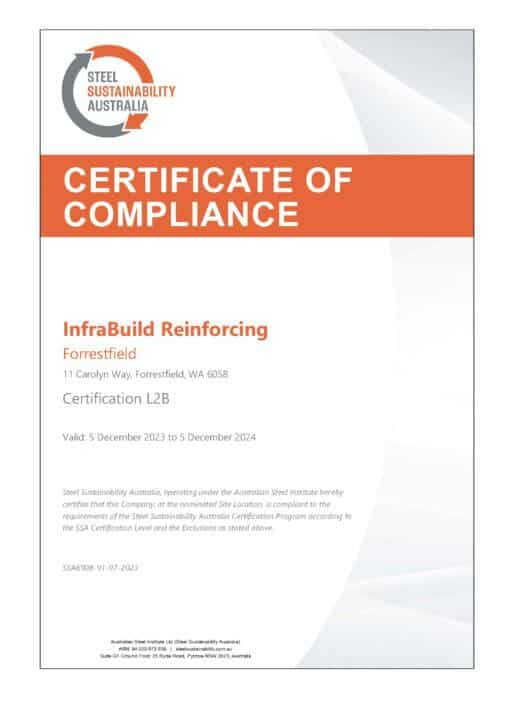

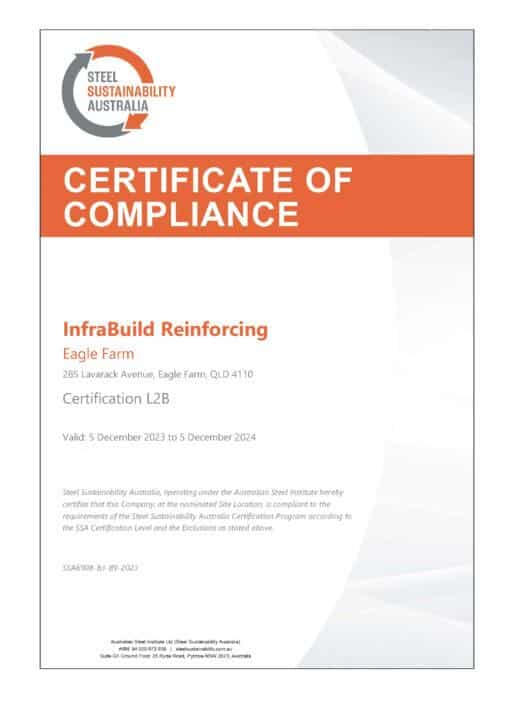

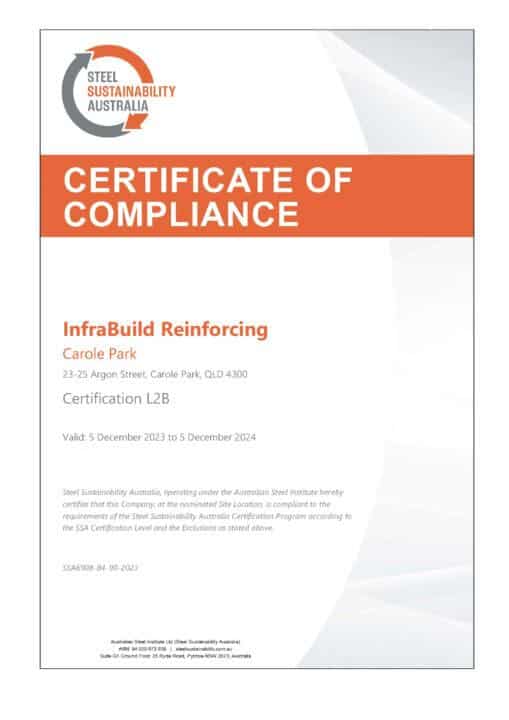

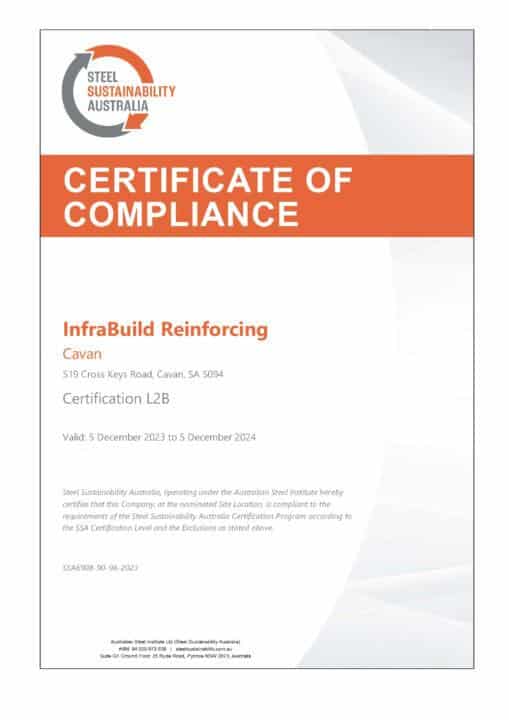

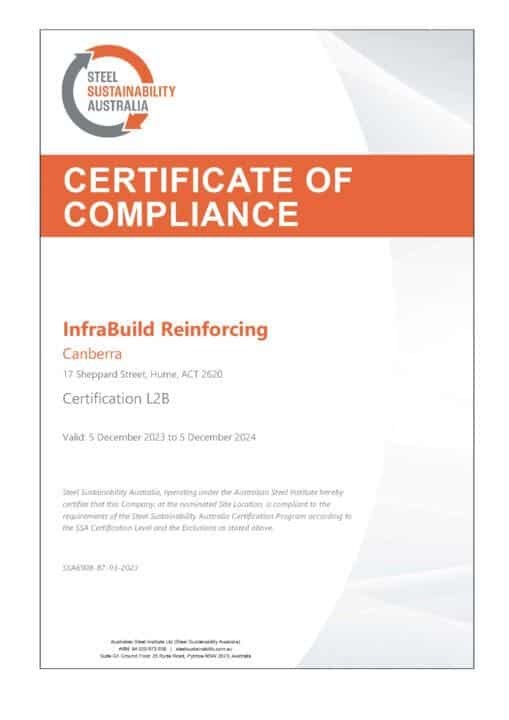

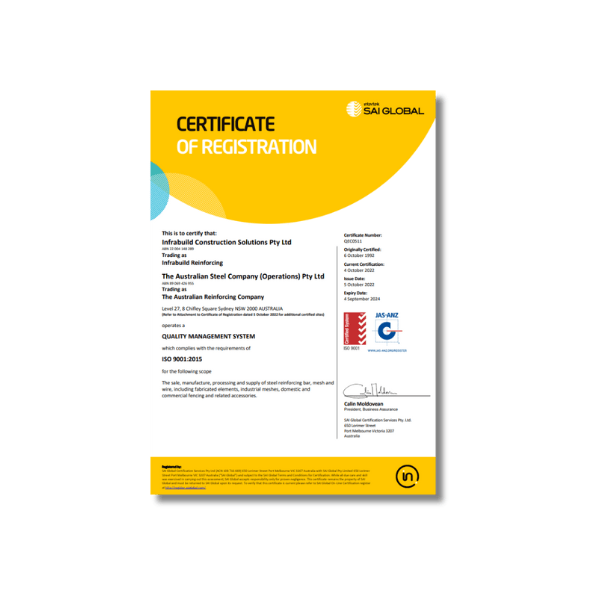

The Australian Procurement and Construction Council (APCC) released the second edition of its A Guide to Achieving Compliance publication in 2015. It outlines a list of industry compliance schemes, including the Australian Certification Authority for Reinforcing Steels (ACRS) scheme, as well as the Steelwork Compliance Australia (SCA) scheme.

The Federal Senate Inquiry on the economic, as well as other impacts of NCPs has been reconstituted, prompted in part by the finding of asbestos at the Perth Children’s Hospital.

The Construction Products Alliance (CPA) continues to make representations to the Building Ministers Forum and other government forums by outlining the extent of the problem posed by NCPs, coupled with recommendations about solutions.

The steel industry continues to work with Standards Australia to update and refine the series of Australian & New Zealand Standards that provide guidance to ensure the safety and long-term reliability of the structures they help build.

Q: What recent improvements have been made to Australian Standards to counter the use of non-compliant building products?

A: In 2016, four Australian Standards relating to the manufacture of structural steels were updated and released, further improving on measures introduced in 2009 and 2010. Among the changes made were those to harmonise the four Standards with each other. Changes included the mandatory requirement that test certificates be made available, and product conformity requirements to prevent regrading of product based on inadequate test data.

Furthermore, a new Standard was introduced relating to fabrication and the erection of structural steel. The AS/NZS 5131 Standard provides a framework for the compliance requirements relating to the fabrication and erection of structural steel, including welding, painting, galvanising and bolting.

Q: What is the role of Steelwork Compliance Australia?

A: Steelwork Compliance Australia was created to accompany the introduction of the new Standard. The role of the organisation is to audit and certify steel fabricators to the necessary levels as stipulated by the National Structural Steelwork Compliance Scheme. This in turn gives clients the ability to select fabricators who have been independently assessed as having the ability to achieve compliance to the relevant Australian Standards.

Q: What do you need to look for when identifying compliant structural steel?

A: In the case of hot rolled structural sections, manufacturers must include a maker’s mark on their product and at regular intervals to meet the requirements of AS/NZS 3679.1. All hot rolled structural sections manufactured at LIBERTY Steel & Mining (formerly LIBERTY Primary Steel), for example, bear the ‘one as’ mark no more than 4m apart.

Labeling must also appear on the product that links it to the test certificate, with minimum levels of information needed at defined intervals.

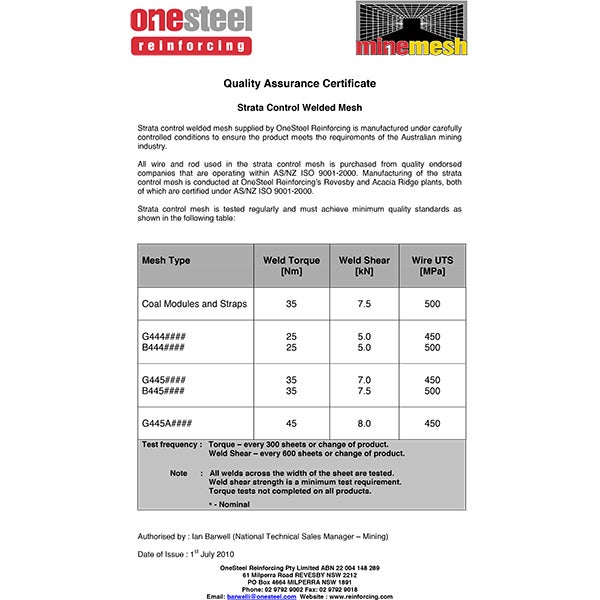

In the case of reinforcing steels, markings on the steel bars identify the product and where it was manufactured. The accompanying bundles stickers will also link the product to the corresponding ACRS certificate.

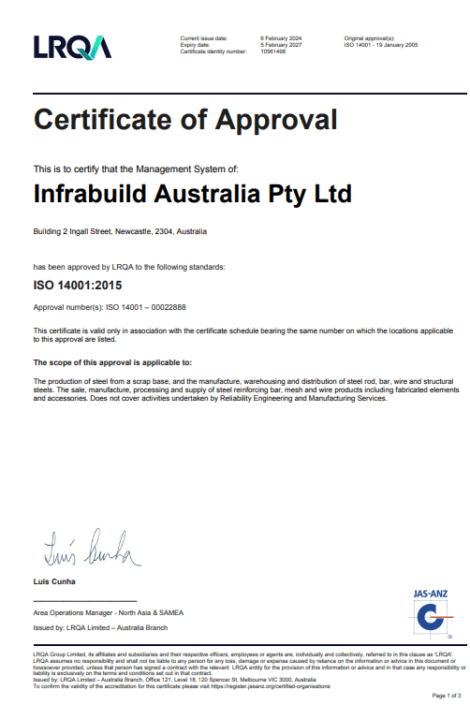

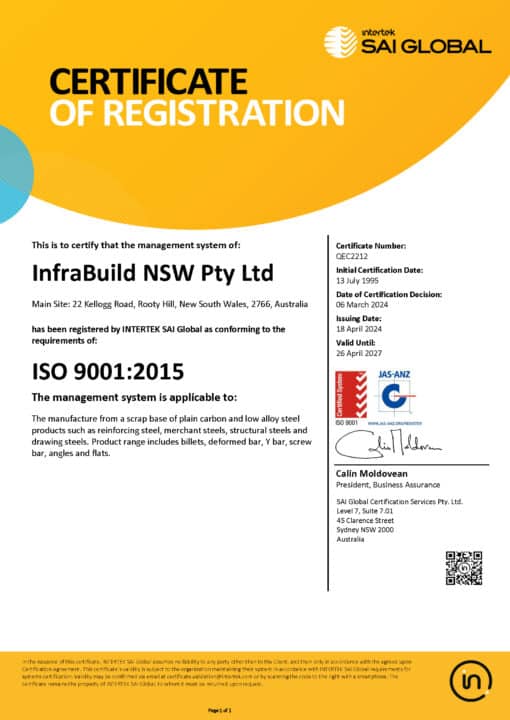

All of InfraBuild’s structural steel, hollow sections, reinforcing steels and pre-stressing strand carry ACRS certification.

The best way to ensure compliance is to specify InfraBuild product and look for the relevant InfraBuild tags and line or bar marking on the products supplied.

Please contact us for any feedback or media enquiries about this content.

Related Resources

Latest Resources

Subscribe to the

InfraBuild newsletter

Receive regular updates on news, case studies as well as the latest products and services.